- Osisko Development (ODV) releases ore sorting test results that confirm increased concentrator and mill grades

- The average combined recovery of gold from all tests was approximately 93.1 per cent and a mass pull of 42.6 per cent

- Using ore sorting as a primary pre-concentration process reduces overall processing costs by removing mechanically, unmineralized material

- The benefits of ore sorting technology are also substantial from an environmental perspective by reducing the energy required for the communition circuit

- Osisko Development Corp. (ODV) is up 0.84 per cent and is trading at C$7.19 at 11:27 am ET

Osisko Development (ODV) has released ore sorting test results that confirm significantly increased concentrator and mill grades.

This test work was aimed at confirming the use of ore sorting to improve the processed grade of mineral resources at the Cariboo Gold Project in Wells, British Columbia.

Osisko Development Corp. commissioned TOMRA in the last quarter of 2020 to complete ore sorting tests using a XRT sensor (x-ray transmission) on a sample of approximately 2,200kg of ore coming from the Cariboo Gold Project.

After screening to remove the fine particles (less than 10mm), approximately 1,800kg of the sample, corresponding to medium grade mineralized material typically encountered around high-grade veins and replacements, was tested by the Tomra Sorter.

For the Cariboo Gold Project, grades higher than 4.0 g/t will go directly to flotation where metallurgical tests yield gold recovery of 98.3 per cent.

Grades lower than 4.0 g/t are sent to a pre-concentration ore sorting process.

Combining the two new tests done at the TOMRA facility with the previous 21 tests done at the Steinert facility in Kentucky, USA, more than 4,700kg of mineralization was tested with commercially available ore sorting technology.

The average combined recovery of gold from all tests was approximately 93.1 per cent and a mass pull of 42.6 per cent.

Using ore sorting as a primary pre-concentration process reduces overall processing costs by removing mechanically, unmineralized material.

In the case of the Cariboo Gold project, this translates to important cost savings on the capital expenditures and operating expenditures for the mill facility by reducing the requirement to process 50 per cent to 60 per cent of the extracted mineral resource tonnage from the mine.

The benefits of ore sorting technology are also substantial from an environmental perspective by reducing the energy required for the communition circuit, the amount of processing reagents and water needed for processing and more importantly, enabling the Cariboo Gold Project to have no tailings storage facility near the community of Wells.

Sorted material can be transported and deposited within the existing waste pile adjacent to the Bonanza Ledge Mine currently in operation.

Sean Roosen, Chair and CEO of Osisko, commented: “These new tests, completed on medium-grade material, demonstrate the potential to provide a higher grade, ore sorter concentrate, at a low cost, to be further upgraded via a standard flotation process, to the planned concentrator facility in Wells, BC.”

“The Sensor Sorting Technology is used in many industries including metals and plastics recycling as well as vegetable and fruit sorting which are far more challenging,” added Roosen.

In the coming months, Osisko Development plans a second ore sorting test at the TOMRA test facility in Wedel, Germany to provide even further confidence for this design improvement of the Wells concentrator.

Osisko also expects to receive approval to begin the development of underground access for a 10,000-tonne bulk sample in the second quarter of 2021.

The bulk sample permit intends to replicate the Cariboo Gold Project’s mining conditions by mining two stopes and processing the mineralized material through an ore sorter on site.

A new ore sorter was purchased in the last quarter of 2020 and is expected to arrive in Wells during the third quarter of 2021 with test work beginning before year-end.

This bulk sample will also allow Osisko Development to continue to test our new, fully electric and automated Sandvik MT720 continuous miner.

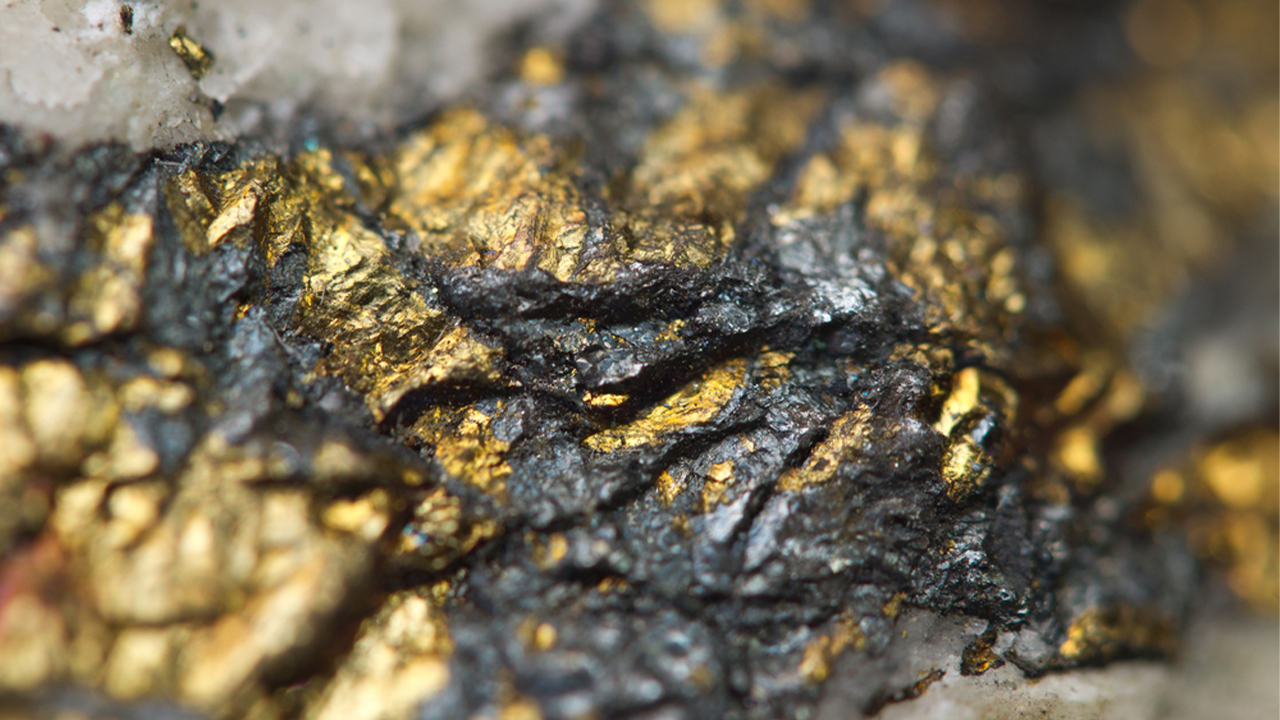

Gold grades are intimately associated with quartz vein-hosted pyrite as well as pyritic, intensely silicified wall rock haloes in close proximity to the veins.

The average grade of the actual veins based on the 43-101 resource update dated October 5, 2020 averages approximately10 g/t Au.

Osisko Development Corp. (ODV) is up 0.84 per cent and is trading at C$7.19 at 11:27 am ET.